- US: +1-408-610-2300

- Toll Free: +1-866-831-4085

- Become a Client

The global medical injection molding market size was worth USD 1.38 billion in 2019. It is anticipated to register a CAGR of 8.2% over the forecast duration, 2020 to 2027. The rise in the demand for metal injection molded components and plastic in the medical sector is driving the growth of the market. In addition, home healthcare popularity is increasing due to its low cost as compared to hospitals care. Therefore, the demand for medical equipment is rising for home healthcare applications. With advancements in the medical industry, different kinds of tests are conducted for diagnosis in hospitals, which in turn, has surged the demand for different medical devices. The United States is one of the major contributors to the market. Factors such as sophisticated healthcare infrastructure, increasing spending on healthcare, and the growing geriatric population are attributing to the growth of the market in the U.S.

Plastic injection molding is used in the production of test tubes, casings & housing for medical equipment & laboratory, beakers, surgical equipment, and implantable components among others. The outbreak of COVID-19 has led to an increase in the demand for various medical devices, thereby, positively affected the market growth.

While manufacturing medical devices, various factors like FDA regulations, ISO certifications & compliance, durability, and material properties are considered. Materials like polyethylene, polypropylene, polycarbonate, and silicone are increasingly used in the manufacturing of medical equipment. The use of both plastic and metal is popular among manufacturers.

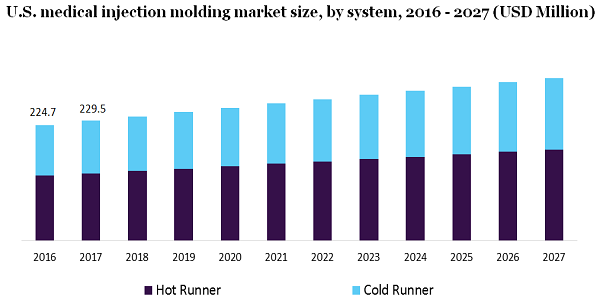

By system, the hot runner accounted for the maximum share in the medical injection molding market with more than 55.0% in 2019. Further, the segment is anticipated to register the highest growth rate over the forecast duration. Hot sprinter molds have two plates that are heated in a complex framework. This system helps in maintaining the level of both warning chamber and liquid thermoplastics at the same level. Owing to this, the hot runner system is gaining traction among manufacturing companies. In addition, the hoy runner system provides other benefits such as lower pressure requirements, increased cycle time, and waste elimination.

On the other hand, the cold runner system has its own advantages such as cost-effectiveness and easy maintenance. Moreover, the cold runner is suitable for different kinds of polymers. Thus, the cold runner is gaining in popularity owing to lower investment and its ability to produce quality parts. In addition, the cold runner system offers flexibility in design and gate locations. However, the hot runner is estimated to grow significantly owing to its high efficiency.

Depending on the class, in 2019, the Class III segment held over 38.0% share in the market. Class III medical devices include respirators¸ ventilators, oxygen therapy devices, and defibrillators. These devices are estimated to witness increased demand owing to the outbreak of COVID-19. In addition, Class III includes heart valves, a cerebral simulator, and pacemakers. Around 10.0% of all medical equipment comes in this category. These devices are designed for easy accessibility, robust cybersecurity control, and the ability to handle injury risk.

Injection molding is increasingly used in the mass production of medical devices and it produces a wide range of medical equipment. This process is capable of producing medical components with precision. Increasing use of injection molding in the production of Class I type of medical devices is projected to positively affect the medical injection molding market growth.

On the other hand, the Class II category is projected to register the highest growth over the forecast duration. Injection molding provides various benefits such as high productivity, lower risk, and increased safety. Therefore, it is widely used in the manufacturing of several kinds of medical devices.

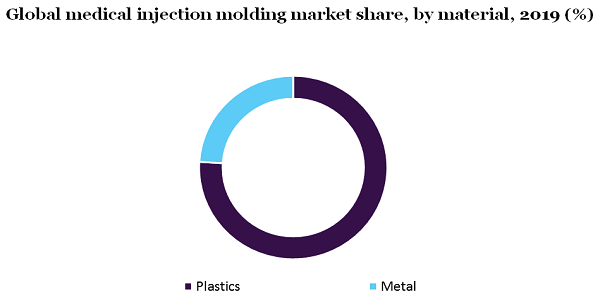

Based on material, the plastic segment accounted for the highest share by revenue with 76.0% in 2019. Materials such as engineering-grade plastic resins offer various benefits such as metal tolerance, temperature resistance, and high tensile strength when used in the manufacturing of pharmaceutical and medical products. In addition, this material offers other advantages such as lower production costs and reduced waste.

Plastic injection molding is capable of manufacturing intricate designs. Medical-grade injection molding products are gaining popularity owing to their durability, resistance to chemicals & contaminants, and cost-effectiveness at a large scale.

Metal injection molding is increasingly used for the manufacturing of small, precise, and complex metal components for the medical industry. This process uses both powder metallurgy and thermoplastic injection molding. In addition, this process is cost-effective as compared to other conventional methods as it reduces the inventory cost, workforce, and material usage.

Further, the product manufactured using the metal injection method has excellent mechanical properties, thereby; this process is gaining traction across the globe. However, material wastage, difficulty in manufacturing complex medical parts, and corrosion are projected to restrain the growth of the segment over the forecast years.

In 2019, Asia Pacific accounted for more than 38.0% share in the global medical injection molding market. Further, the region is anticipated to register the highest growth over the forecast years, 2020 to 2027. Factors such as growing medical tourism, an increasing number of people preferring home care, and rising spending on healthcare are attributing to the growth of the region.

On the other hand, North America accounted for over 23.0% share in the market in 2019. An increase in the number of people affected due to the COVID-19 in the United States is anticipated to positively affect the market growth over the next few years. The government is estimated to increase its budget on healthcare infrastructure post-COVID-19. Increased spending on healthcare is likely to supplement the demand for medical devices and related equipment. In addition, Mexico is anticipated to witness increased demand for medical devices owing to the increasing geriatric population and growing prevalence of cardiovascular diseases in the country.

The market has been positively affected owing to the outbreak of COVID-19. Globally, hospitals have witnessed increased patient counts as a large number of people have been diagnosed with COVID-19. The pandemic has led to an increase in the demand for medical devices. Medical equipment such as ventilators, respirators, and oxygen therapy equipment has witnessed rapid growth in their demand. Thus, increasing demand for medical devices has led to an increased in the production of these devices, which in turn, has fueled the growth of medical injection molding. In addition, the demand for medical equipment is estimated to raise post-COVID-19 as government authorities are anticipated to increase their investment in the healthcare infrastructure.

Industry players are focusing on the introduction of new products, mergers & acquisitions, and technical advancements to consolidate their position. For example, Milacron Holdings Corp. acquired Hillenbrand Inc. in 2019 in a deal worth USD 2.0 billion to enhance the former’s product portfolios. Key players operating in the market are Proto Labs, Inc., HTI Plastics, ENGEL AUSTRIA GMBH, C&J Industries, and Milacron among others.

|

Report Attribute |

Details |

|

The market size value in 2020 |

USD 1.51 Billion |

|

The revenue forecast in 2027 |

USD 2.59 Billion |

|

Growth Rate |

CAGR of 8.2% from 2020 to 2027 |

|

The base year for estimation |

2019 |

|

Historical data |

2016 - 2018 |

|

Forecast period |

2020 - 2027 |

|

Quantitative units |

Revenue in USD million and CAGR from 2020 to 2027 |

|

Report coverage |

Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

|

Segments covered |

System, class, material, region |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country scope |

The U.S.; Canada; The U.K.; Germany; France; Italy; Spain; Australia; China; India; Japan; South Korea; Argentina; Brazil; Colombia; Mexico; Saudi Arabia; South Africa; UAE |

|

Key companies profiled |

C&J Industries; HTI Plastics; AMS Micromedical LLC; Currier Plastics Inc.; Proto Labs, Inc.; Metro Mold & Design Inc.; Harbec, Inc.; Milacron; ENGEL AUSTRIA GMBH |

|

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail of customized purchase options to meet your exact research needs. |

This report forecasts revenue growth at global, regional, and country levels, and provides an analysis of the latest industry trends in each of the sub-segments from 2016 to 2027. For this study, Million Insights has segmented the global medical injection molding market report based on system, class, material, and region:

• System Outlook (Revenue, USD Million, 2016 - 2027)

• Hot Runner

• Cold Runner

• Class Outlook (Revenue, USD Million, 2016 - 2027)

• Class I

• Class II

• Class III

• Material Outlook (Revenue, USD Million, 2016 - 2027)

• Plastic

• Metal

• Regional Outlook (Revenue, USD Million, 2016 - 2027)

• North America

• The U.S.

• Canada

• Europe

• The U.K.

• Germany

• France

• Italy

• Spain

• The Asia Pacific

• Japan

• China (Mainland)

• India

• Australia

• South Korea

• Latin America

• Brazil

• Mexico

• Argentina

• Colombia

• Middle East & Africa

• South Africa

• Saudi Arabia

• UAE

Research Support Specialist, USA